1.2 Chassis Options

-

Type A/B NETS Chassis/

Metric Chassi / Waterford Based Chassis

-

-

GM 1978-1987 G Body 108 inch Metric Frame with all suspension

points retained to manufacturer specs. Must be able to pass

inspection using Johnson Chassis inspection tools.

- Frame may be

fabricated forward of the front spring buckets.

-

A/B

Replacement of the rear frame from aft side of spring pocket

perch allowed. with Minimum 2x3 x 0.90

-

Replacement tubing of the rear frame must

maintain a minimum of 8 inches ground clearance.

-

Section must maintain width equal or greater

than distance between outside of rear spring

bucket. Rear frame between rails must use same

size tubing.

-

C Channel may be boxed.

- C Channel may be replaced with 0.125 square tubing .

- Minimum 2 inch X 3 inch allowed .

- 3inch X 4 inch tubing is preferred.

- Rear Shelf Metric (A/B/S)

- There is no penalty of removing or

altering the rear shelf

- Please note : removal of the shelf alters the

rear clip strength. A tie in replacement

tubing that runs from side to side in place of

the shelf is recommended..

- 1.3 Chassis replacement components

- Frame

Type A / NETS Chassis/

Type B

/S Metric

- Johnson Chassis

78-89

GM-METRIC FRAME

-

4-Link

- OEM 225lbs

- 3" X 4" x

.125 Main Frame Rails

-

(Must

be purchased through NET or

authorized chassis dealer)

- Front Clip

Type A / NETS Chassis/

Type B

/D

- Johnson

Chassis X-Y-G Metric Front Clip

-

GM-METRIC

TUBULAR REPLACEMENT

-

O.E.M

DIMENSIONS & WEIGHT

-

USES

OEM OR TUBULAR COMPONENTS

-

MOTOR

MOUNTED IN O.E.M. LOCATION OR 3 SETBACK TO # 1 PLUG

-

LOWER

A-ARM SLOTTED FOR WHEELBASE

SLUGS 0-1/4

-

(Must

be purchased through NETS or authorized chassis dealer)

-

Hamm

GHC 5108

-

Hamm

GHC 54108

- Howe 358-08-01 F Body Front Frame

- Engine must be at 11 inch

crank height

-

All Howe tags and logo must be in tact

- Team must contact Howe and supply inspection diagram

-

Howe

35819 Chevelle Type Front Frame C/D

Chassis

-

All Howe tags and logo must be in tact

- Team must contact Howe and supply inspection diagram

- Howe 35809 Impala Type Sub Frame

C/D

Chassis

-

All Howe tags and logo must be in tact

- Team must contact Howe and supply inspection diagram

- Any snout may be submitted for approval.

- Rear Clip

Type ANETS Chassis/

Type B/D

- Johnson

Rear Replacement Frame allowed

-

(PREFORMED

2X 3X .125

-

CLEARANCED

FOR BRAKE CALIPERS 15 TALL SPRING BUCKETS )

4-LINK W/BUCKETS

-

W/KICKERS

AND TRAILING ARM MOUNTS

-

Verified Johnson Rear Frame mounts unaltered will

be considered stock\

- Rear shelf

- note: removal of the shelf alters the

rear clip strength. A tie in replacement

tubing that runs from side to side in place of

the shelf is recommended..

1.4 Roll Cage / Chassis/ Frame

- Main Cage Tubing (Halo, Front and Rear Main Hoop,

Ear bar, Door Bar)

- 1 and 1/2 with minimum .120 wall tubing

- 1/3/4 with minimum .090 tubing

- Halo must be within 4 inches of front edge of roof

- Front Hoop to Ball joint measurement maximum 28

inches

- Rear Hoop to center of rear axle minimum 32 inches

- Distance from top of frame to bottom edge of rear

hoop minimum 40 inches.

- Ear bar must be no more than 6 inches forward of

rear main hoop (b Post)

- All welds must be complete

- X method for Right/Passenger side door bars is

allowed

- Drivers Door Requirements

- Minimum 4

- Must be plated with minimum .125 thickness steel

- Minimum height of door bars from frame to top of

bars, 22 inches

- Padded with proper resilient padding

- Trucks built after Feb 1 of 2016 must have

- Continuous diagonal bar extending from drivers

side top corner of rear main hoop to the base of the

rear rear main hoop on the passengers side.

- Anti bow bars must be installed to support the

diagonal brace.

- Front down tube minimum wall thickness is .083

- Must extend forward past front spring buckets

- Recommended to align with top driver's door bar

- No excessive bracing

- Aft of main hoop

- Minimum 4 back stays

- Minimum wall thickness .083

- Recommend 2 back stays align with top drivers

door bar and extend to area of rear spring bucket

- Recommend to back stays run from top of main

hoop to frame.

- Fuel cell protection bar mandatory

- Bumpers

- Single tube - front conforming to nose

- Single tube - rear conforming to bumper cover

- Must contour to body

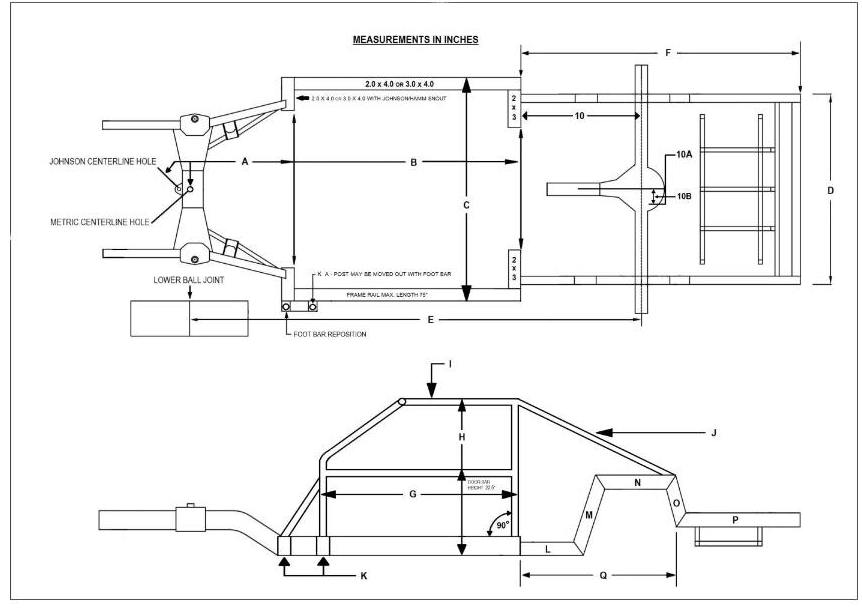

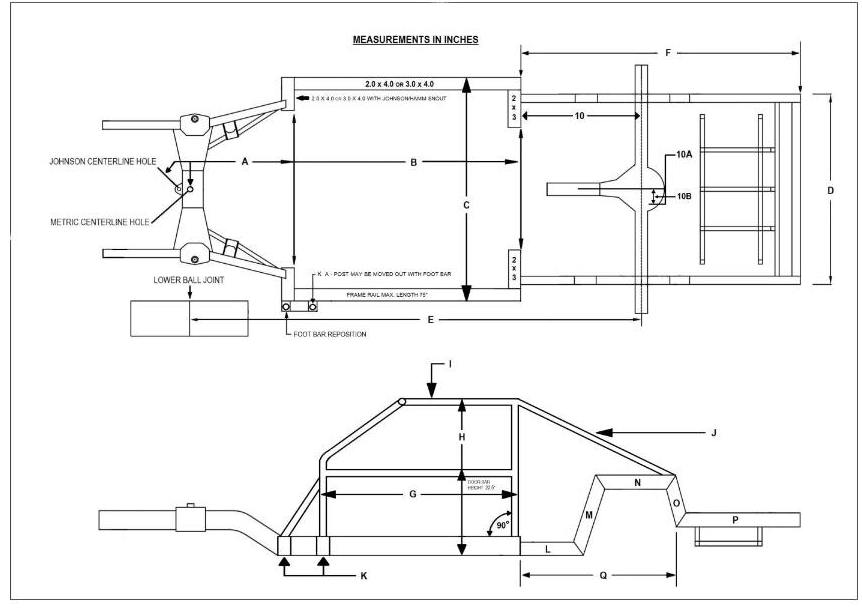

- Seekonk-Metric

- A- Centerline hole, Forward placement of snout will

use two holes for measurements. OEM - 26.5".

Johnson/Hamm - 27.125". +/- ½". Snout MUST be centered

to FRAME and REAR CLIP, NO tolerance.

B- Frame rail lengths, from snout centerline hole to end

of rail - 75" Maximum.

C- Chassis frame rails width outside to outside Max

54.0" +/- ½".

D- Rear clip outside to outside 42.0". Mounted centered

to front snout.

E- Wheelbase length 102.0" minimum. No tolerance.

F- Rear clip length 66.0". +/- ½".

G- Roll cage length, measured outside of main posts -

44.5". +/- ½".

H- Roll cage height: top of cage to bottom of chassis -

47.0". +/- ½". The cage must stand at 90 degrees

to the chassis and not go further back than frame rails

allow at 74.5". Refer to (B)

I- Roll cage halo 44.0" length / 29.5" width. +/- 1.0".

J- Down bars from main cage - top 38.0" outside to

outside +/- 1.0". Bottom attaches to end of chassispiece

(N). Bars may intersect with other bars before

connection to chassis.

K- Roll cage A-post leg and foot bar maybe moved 3.0" to

outside of main frame rail. 2 x 4 tubing .120"

wall, must be used under the repositioned bars welded

off main frame rail or in front of kickout. This is

the only portion of the cage allowed to be repositioned,

giving more leg room to the driver.

Rear clip consists of 5-pieces L thru P using 2" x 3"

.083" steel box tubing. All angles are with 36-degree

cuts. Listed are the lengths of each piece before angle

cuts are made. Dont forget to factor in blade widths

of saw when measuring.

L- 18"

M- 18"

N- 19"

O- 10"

P- 25"

Q- Length between L to O rear clip 41"

-

Type

C

- FRAME: 1965-2015 American production full

frame cars -wheelbase between 108 and 112 inches.

-

Alteration to obtain 112" wheelbase allowed

( must be within 12 inches of the rear mount points

of the rear trailing arms.)

-

Frames

may be interchanged from one manufacturer's line or

make to another

- Front and rear snouts must remain stock for make of

frame.

-

Cross member cannot be moved from original location

, altered or out of tolerance

-

will be measured and verified by officials for year,

make and model.

- No sub-frames / No Offset Frames

- Rear frame section must be stock configuration with

reinforcement permitted after rear of mount points of

rear trailing arms.

- Altered rear kick-up permitted for axle clearance.

- Frame rails

-

Must remain hollow. No added bracing, tubing

permitted inside the frame rail.

-

No holes may be cut in the frame rails to lighten

frame.

-

will be measured and verified by officials for year,

make and model.

-

Two inch by four-inch steel tubing is permitted from

the center of the rear axle to the rear bumper.

-

Two inch by four-inch steel tubing may be used in

front of the steering box and A-frame mounts.

- 1.4 Roll Cage / Chassis/ Frame

- Main Cage Tubing (Halo, Front and Rear Main Hoop,

Ear bar, Door Bar)

- 1 and 1/2 with minimum .120 wall tubing

- 1/3/4 with minimum .090 tubing

- Halo must be within 4 inches of front edge of roof

- Front Hoop to Ball joint measurement maximum 28

inches

- Rear Hoop to center of rear axle minimum 32 inches

- Distance from top of frame to bottom edge of rear

hoop minimum 40 inches.

- Ear bar must be no more than 6 inches forward of

rear main hoop (b Post)

- All welds must be complete

- X method for Right/Passenger side door bars is

allowed

- Drivers Door Requirements

- Minimum 4

- Must be plated with minimum .125 thickness steel

- Minimum height of door bars from frame to top of

bars, 22 inches

- Padded with proper resilient padding

- Trucks built after Feb 1 of 2016 must have

- Continuous diagonal bar extending from drivers

side top corner of rear main hoop to the base of the

rear rear main hoop on the passengers side.

- Anti bow bars must be installed to support the

diagonal brace.

- Front down tube minimum wall thickness is .083

- Must extend forward past front spring buckets

- Recommended to align with top driver's door bar

- No excessive bracing

- Aft of main hoop

- Minimum 4 back stays

- Minimum wall thickness .083

- Recommend 2 back stays align with top drivers

door bar and extend to area of rear spring bucket

- Recommend to back stays run from top of main

hoop to frame.

- Fuel cell protection bar mandatory

- Bumpers

- Single tube - front conforming to nose

- Single tube - rear conforming to bumper cover

- Must contour to body

-

Type

D

(Street Stock Conversion)

-

- Any American made production chassis with a minimum stock

wheelbase of 101- 110" inches, from 1972 to current date.

- Chassis may not be altered from stock appearance unless

noted in the rules.

- No alteration/moving of chassis suspension mounting

points or spring locations

- Cross-member may be only altered for engine clearance.

- Reconstruction of chassis permitted from steering box

forward .

- Reconstruction of chassis permitted from center of rear

wheels back.

- Replacement tubing of the rear frame must

maintain a minimum of 8 inches ground clearance.

- Construction must resemble stock placement.

- Minimum 2" X 3" steel box tubing .090 thickness may

be used.

- No bars may travel under rear end housing.

- Section must maintain width equal or greater

than distance between outsides of rear spring

buckets. Rear frame between rails must use same

size tubing.

- Wheel base must be altered to 108 inches

with 1 tolerance.

- The use of X-Y-G Mandrel bend Johnson chassis with no

modifications is permitted.

- The use of DCA racefab as manufactured

- Front mandrel bend clip assemblies from Johnson & DCA

may be used on stock metric chassis.

- Uni-body chassis must use sub-frame connectors.

- C Channel may be boxed.

- C Channel may be replaced with 0.125 square tubing .

- Minimum 2 inch X 3 inch allowed .

- 3inch X 4 inch tubing is preferred.

- Chassis is eligibility is based on existing

street stock being converted. Cage must be

constructed by guidelines of original rules for the

street stock being converted and also conform with the

rules below. WTC officials may refuse any chassis

at their discretion.

- Main Cage Tubing (Halo, Front and Rear Main Hoop,

Ear bar, Door Bar)

- 1and 3/4 with minimum .090 wall tubing

- 1 and 1/2 with minimum .120 wall tubing

- Ear bar must be no more than 6 inches forward of

rear main hoop (b Post)

- All welds must be complete

- X method for Right/Passenger side door bars is

allowed

- Drivers Door Requirements

- Minimum 4

- Must be plated with minimum .125 thickness steel

- Minimum height of door bars from frame to top of

bars, 22 inches

- Padded with proper resilient padding

- Front down tube minimum wall thickness is .083

- Must extend forward past front spring buckets

- Recommended to align with top driver's door bar

- No excessive bracing

- Aft of main hoop

- Minimum 4 back stays

- Minimum wall thickness .083

- Recommend 2 back stays align with top drivers

door bar and extend to area of rear spring bucket

- Recommend to back stays run from top of main

hoop to frame.

- Fuel cell protection bar mandatory

- Bumpers

- Single tube - front conforming to nose

- Single tube - rear conforming to bumper cover

- Must contour to body

|

- Type C

-

FRAME: 1965-2015 American production full

frame cars -wheelbase between 108 and 112 inches.

-

Alteration to obtain 112" wheelbase allowed

( must be within 12 inches of the rear mount points

of the rear trailing arms.)

-

Frames

may be interchanged from one manufacturer's line or

make to another

-

Front and rear snouts must remain stock for make of

frame.

-

Cross member cannot be moved from original location

, altered or out of tolerance

-

will be measured and verified by officials for year,

make and model.

-

No sub-frames / No Offset Frames

-

Rear frame section must be stock configuration with

reinforcement permitted after rear of mount points of

rear trailing arms.

-

Altered rear kick-up permitted for axle clearance.

-

Frame rails

-

Must remain hollow. No added bracing, tubing

permitted inside the frame rail.

-

No holes may be cut in the frame rails to lighten

frame.

-

will be measured and verified by officials for year,

make and model.

-

Two inch by four-inch steel tubing is permitted from

the center of the rear axle to the rear bumper.

-

Two inch by four-inch steel tubing may be used in

front of the steering box and A-frame mounts.

- Main Cage ( Halo, Front and Rear Hoop, Ear bar and

Door bars)

- 1and 3/4 inch with minimum 0.90 wall tubing

- Distance between main hoops must be 53 inches

- Brain bar must be added

- Center windshield bar mandatory

- Door bars

- 4 driver's door bars

- 3 Right Side door bars

- Bumpers

- Single tube - front conforming to nose

- Single tube - rear conforming to bumper cover

- Must contour to body

- Type Seekonk-Sport (Except new Seekonk Metric)

- Main Cage Tubing (Halo, Front and Rear Main Hoop,

Ear bar, Door Bar)

- 1and 3/4 with minimum .090 wall tubing

- 1 and 1/2 with minimum .120 wall tubing

- Ear bar must be no more than 6 inches forward of

rear main hoop (b Post)

- All welds must be complete

- X method for Right/Passenger side door bars is

allowed

- Drivers Door Requirements

- Minimum 4

- Must be plated with minimum .125 thickness steel

- Minimum height of door bars from frame to top of

bars, 22 inches

- Padded with proper resilient padding

- Front down tube minimum wall thickness is .083

- Must extend forward past front spring buckets

- Recommended to align with top driver's door bar

- No excessive bracing

- Aft of main hoop

- Minimum 4 back stays

- Minimum wall thirstiness .083

- Recommend 2 back stays align with top drivers

door bar and extend to area of rear spring bucket

- Recommend to back stays run from top of main

hoop to frame.

- Fuel cell protection bar mandatory

- Bumpers

- Single tube - front conforming to nose

- Single tube - rear conforming to bumper cover

- Must contour to body

- Chassis Weight -All trucks must be specified minimum

weights and percentage at all times

.

- Automatic`/ Standard Transmission 2900 lbs

- Weight Tolerances: None

- Maximum left side weight percentage 56%

- Wheel base 102

inches

- Add 10 lbs for every inch / 5 lbs per 1/4 inch

under 108

- Ground Clearance

- All components / body parts

must maintain a minimum of 4 inches ground clearance.

- Chassis 4 inches

- Fuel Cell 7 inches

- Exhaust 4 inches

- Crankshaft height / placement

- Centered between frame rails

- Engine location

- Forward most spark plug must be even or forward

of an imaginary line between ball joints.

|